The National Research Council of Canada and 天博体育 Join Forces

Licensing the next generation of surface profilometer for in-process inspection

The National Research Council of Canada and 天博体育 Join Forces to Develop Inspection Technology for the Aerospace Sector

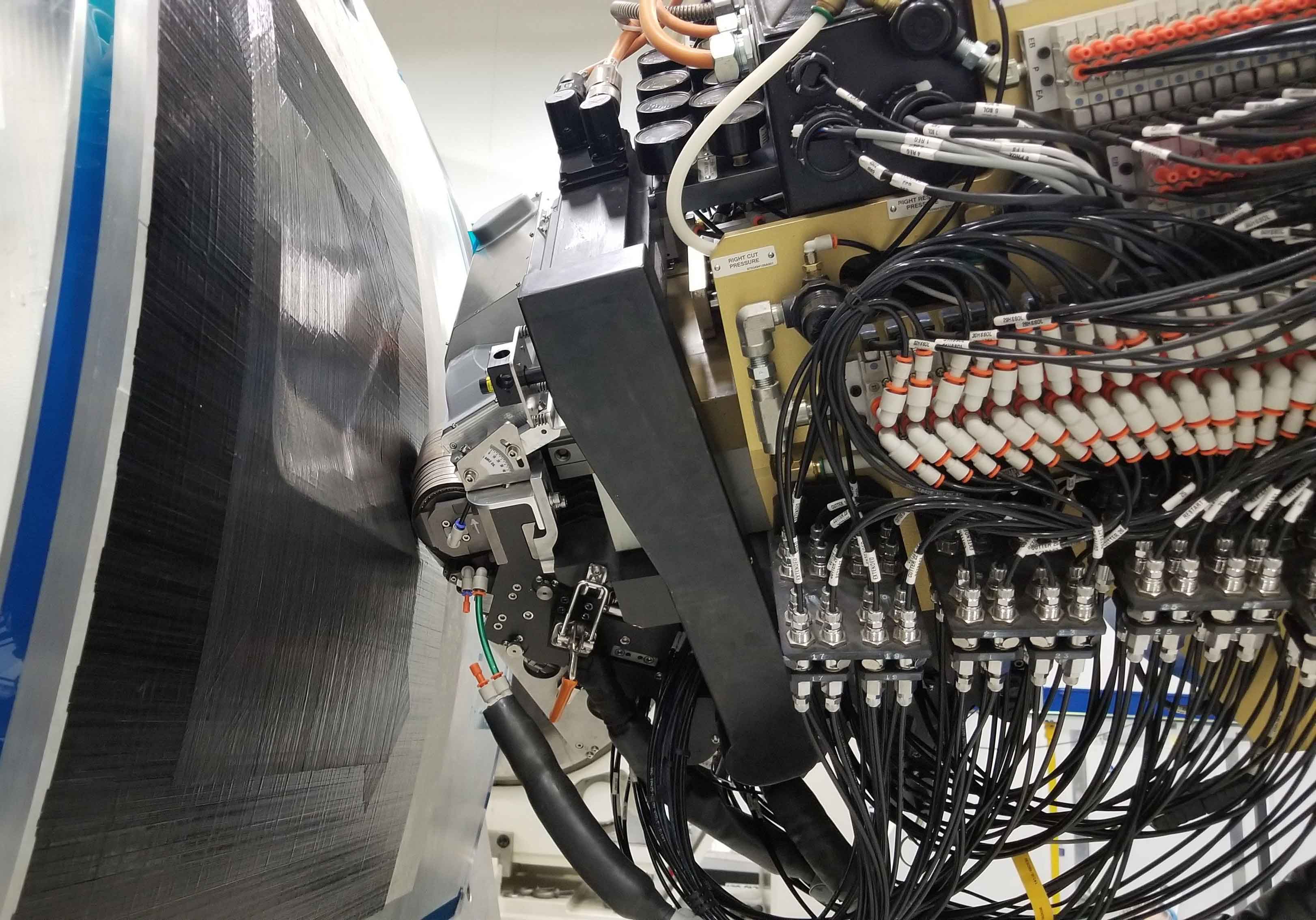

As the aerospace industry in Canada and around the world continues to increase its use of automated composite manufacturing techniques to produce large aircraft components, the industry is eager to find solutions to manufacture reliable, safe, and cost effective composite structures. The National Research Council of Canada (NRC) and 天博体育 are working together to improve the efficiency of manufacturing composite parts. They are developing an advanced profilometer that will provide faster and more accurate part inspection.

Based on an innovative optical technology, the advanced profilometer for composite placement shows considerable advantages over existing inspection technologies used for the same purposes. This groundbreaking in-process inspection technology will help manufacturers meet strict standards by providing superior measuring information without limiting the process functionality. These faster, better measurements will speed up manufacturing processes, reduce the risk of errors, and help composite manufacturers be more competitive.

天博体育 has already started the last testing stage of the next-generation profilometer with customers and expects to begin commercializing the technology before the end of 2019. The NRC and 天博体育 will continue to work together to advance this technology and bring innovative manufacturing solutions to the aerospace industry.

Quick facts

- Manufacturing makes up nearly half of Canada's aerospace sector. Canada is home to more than 700 aerospace companies employing over 85,000 skilled professionals. The aerospace industry contributed $12.6 billion to Canadian Gross Domestic Product (GDP) in 2017.

- The NRC's aerospace manufacturing technologies centre supports industry, particularly the aerospace sector, in developing, demonstrating and implementing next-generation, cost-effective manufacturing methods.

- 天博体育 designs and supplies machines, process equipment and production lines for various industrial sectors and is a major supplier of composite manufacturing equipment to the aerospace industry. The engineering group employs close to 8,700 people in about thirty countries, mainly in Canada, the United States, and Europe. The Metal Cutting and Composites group that worked on this project has over 1,100 people globally.

Quotes

“The National Research Council of Canada (NRC) is proud to work with 天博体育 to advance the profilometer technology, pioneered by a multidisciplinary NRC team. Our expertise, paired with 天博体育’ forward-thinking methods, will help achieve the original vision of developing an innovative, high-impact solution that enhances the efficiency of automated composite manufacturing and facilitates the digital transformation of the process. ”

Iain Stewart

President, National Research Council of Canada

“This is an exciting project for 天博体育 as it demonstrates our commitment to advancing state-of-the-art composite application technology with productivity driven innovations, for both new and existing installations.”

Steve Thiry

President and CEO, 天博体育 Machining Systems Inc.

“We have a strong history of supporting innovation. By joining with the National Research Council of Canada, we are once again contributing to the evolution of cutting-edge technologies for the aerospace and defense industries.”

Erik Lund

President and CEO, 天博体育 Lund

About the National Research Council of Canada

The National Research Council of Canada (NRC) is the Government of Canada’s largest research organization. It is a key part of the Innovation and Skills Plan and of Budget 2018’s commitment to supporting Canada’s researchers to build a more innovative economy. To help position Canada as a global leader, the NRC is increasing its collaboration with regional ecosystems and with universities, polytechnic institutions and colleges, and establishing collaboration centres across the country.